ASIS GmbH

Knowledge Management and QM at ASIS GmbH – a Use Case.

The ASIS GmbH from Landshut is active in the field of automation technology. The focus of the medium-sized company is on surface technology for the automotive industry. ASIS develops and produces painting and sanding systems, among other things, with currently around 130 employees.

We spoke with Jana Timinger, technical editor at ASIS GmbH, about how knowledge and quality management have changed due to the growth of the company.

Ms Timinger, ASIS has undergone a number of changes in recent years. Which challenges have arisen as a result?

We have grown from 70 to 120 employees within a few years. In addition, we have two locations and many employees who spend a lot of time away from home on construction sites or with customers. Here it is always an issue of how we can organize cooperation across distances well, for example in projects where planners from several locations work together. Generally speaking: how do all employees regularly receive important information and how can documents be made centrally accessible and retrievable? Our previous filing structure was not ideal for this.

Industry

Machines, equipment

Market

Manufacturer

Headquarters

Landshut, Germany

Employees

130

Product

Goal

Optimization of the quality management

Use case

Website

Phone

+49 (0) 871 / 2 76 76-0

Portrait

Since its foundation in 1998, ASIS Automation Systems & Intelligent Solutions GmbH has its roots in the automation and process control of industrial manufacturing processes.

Our headquarter is in the city of Landshut. We have a branch in Oldenburg, a technical office in Altdorf near Stuttgart and a subsidiary in China, near Shanghai. Together we realize projects for our international clientele with people who are able to think flexibly and unconventionally. This is exactly our strength.

We are specialists for innovative automation solutions, painting technology, plant construction as well as engineering and are one of the renowned suppliers of complete solutions for the worldwide automotive and supplier industry.

But also detail and niche solutions for the power supply, general and food industry are not unknown to us. We can therefore look back on steadily growing employee and turnover figures.

What was the trigger that prompted you to look for a system to solve these challenges? And what were your requirements for the system?

The initial impetus was quality management. There we had documents in a kind of intranet. That wasn’t very convenient and we were very dissatisfied with it because there was a lot of double filing and the documents were not easily accessible for the employees. In addition, our specialist departments wanted to be able to store knowledge centrally so that it could be accessed by everyone in the department, but also company-wide. This is because Word documents are simply lost far too quickly somewhere on the server – they can hardly be found.

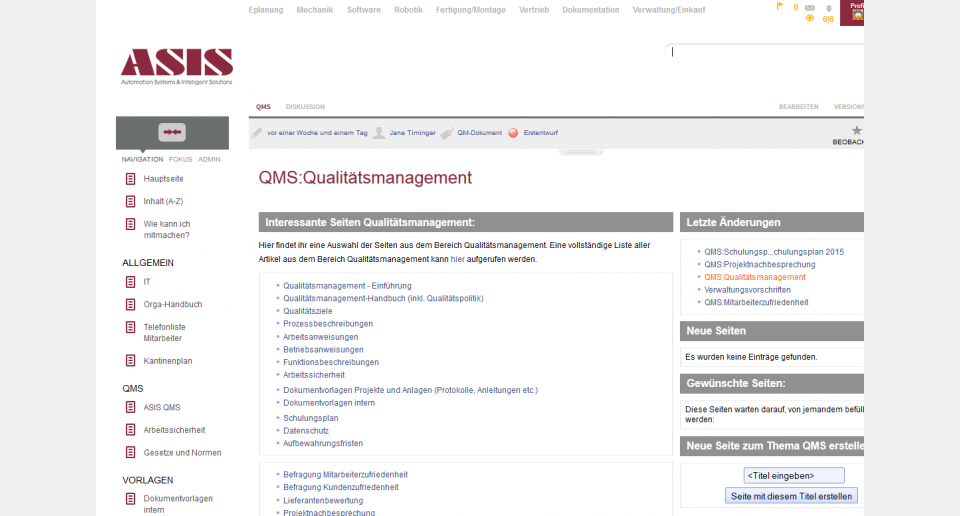

Now all quality management documentation takes place in the wiki and we have set up sub-portals for the individual departments, where the specialist departments can post and highlight relevant information and news.

Screenshot: The Asis quality management portal in the BlueSpice Wiki

And we previously had an organization manual in Word with internal company regulations, pictures of employees and the like – this has also been completely transferred to the wiki.

The main requirement for a new solution was that it had to be easily accessible for everyone who had to read it. The retrievability of documents and information was to be significantly improved (e.g. through a full-text search) and it was also particularly important that redundant data storage should be avoided in the future. And we should ensure that everyone who wants to be active can work without any obstacles.

ASIS has now been using the BlueSpice wiki software since summer 2014. Which departments are involved and who is responsible for the wiki and its contents?

We have defined a person responsible for the general maintenance and organization of the wiki and as contact person for other employees, that’s me.

Of course, our IT department takes care of the technical part, but the support effort for the system after implementation is very low. The specialist departments, such as the electrical and mechanical design departments, in turn independently enter content that they want to document and simply make more widely known within the company.

Otherwise, every employee can suggest content that he or she would like to have in the system – and of course every employee can also enter content himself or herself. We deliberately have a very flat rights system, so that theoretically every employee can contribute in every area, except for the quality management area. So it is also allowed to write across departments, because it happens again and again that, for example, an employee from the software area has knowledge that is also interesting for electrical design. And the last area for the time being is administration, which is primarily concerned with the contents of the organization handbook.

You are respeonsible for the quality management now, right?

Yes, I am. We are ISO 9001 certified and I take care of the documentation of the quality management. We have also moved this area completely to the wiki. Here we use semantics and almost completely dispense with Word documents, since we can read and evaluate metadata such as creator and reviewer clearly and easily in the Wiki. This is a considerable improvement. With just one click someone can get an overview. This is also great for the audit. And future maintenance will be much easier.

Many companies overestimate the effort and planning required to introduce such a system. Can you briefly outline the phases from planning to the current status today?

From the definition of the criteria and requirements to the first workshop with Mr. Heigl from Hallo Welt! and the final decision for the wiki software BlueSpice took about 3 months. This was followed by about 2 months for the technical implementation and the first user training. In addition to this training of the key users, we also held internal training courses to involve many employees as early as possible so that they could get to know the system. Afterwards we transferred existing contents into the Wiki, which took about 3-4 months, because we concentrated on transferring some areas completely into the Wiki, e.g. the entire QM and administration area. We tried to make existing documents and procedures redundant as quickly as possible, so that really everything can be found in the Wiki and Word and Excel documents are superfluous.

Currently we have 1,337 articles in the wiki and are quite satisfied with this “first version”, but we still have a lot of plans – there is still a lot of content that will be found in the Wiki sooner or later. But there are also some cleanup efforts to be done and we are still weighing up what is in good hands in the Wiki. By the way, one of the most popular pages in the Wiki is the canteen map and the telephone list.

What has changed after one year with the wiki?

It is very helpful if the things are kept in one place, because most of the things someone asks for can be referred to the wiki. For example, there are now IT tips in the wiki, so that standard questions do not have to be answered individually all the time, which saves lots of time. A lot of information, and such seemingly minor things as employee pictures, are now much more readily available across locations. The contents of the organization handbook are also enhanced by the wiki and are viewed more frequently.

It is also very nice that employees who are travelling now know what’s new when they return – a lot of information is now visible, whereas it used to be lost. In addition, e-mails have often been sent in the past, which of course often passed by newly arrived colleagues. Now, with the Wiki, new employees have a point of contact for many of their questions.

What are your “lessons learned” in the introduction and implementation of such a knowledge and quality project?

It was good that we were able to transfer content very quickly and abolish other systems immediately – this way we avoided duplication. Also, people are forced to look at the wiki. Unfortunately, it is still the case that some people use the wiki, but still put a “security document” on the server – this should be prevented even more effectively.

The general acceptance of the wiki is good. Almost everyone reads the wiki – but writing is something else. Many still have some inhibitions about writing in the wiki because they are afraid the article might be too long or too short, or they are afraid of breaking something, etc. But once they have learned how to do this, employees use the wiki, too. That’s why I started out by providing individual training for key employees. And we continue to focus on training to further familiarize people with the system. Above all, the department heads play an important role, as they should set an example. Nor should it be the case that employees have to justify themselves to their department heads when they document important knowledge in the wiki.

The last, first year of Wiki was quite intensive. What’s up now? A break?

No, certainly not that. First of all the QM audit is coming up and then the focus will be on the conversion to the new ISO standard. At the same time, further content is to be bundled in the Wiki so that other areas on the server can be shut down. And I will continue to think about how I can bring more people into the wiki, e.g. there is the newsletter of the management in which new employees are introduced, which we could replace with the blog that is provided by the wiki. The wiki is supposed to live and that includes regular maintenance.

We wish you success and thank you for the interview.

Share This Story, Choose Your Platform!

| Except where otherwise noted, news on this site is licensed under a Creative Commons Attribution 4.0 International license. |

More success stories

Organization manual for Tennet TSO

Initially intended as a reference book for the network operator’s construction and operating guidelines, BlueSpice has developed into a company-wide knowledge base with currently around 11,000 articles.

Read more

+

Organization manual for terranets bw GmbH

Six years ago, the network operator terranets bw transferred its organizational manuals and corporate guidelines into a BlueSpice MediaWiki. This saves the company valuable time.

Read more

+

IMS for Wiener Wohnen

Europe's largest municipal property management company has transferred its organisation manual as well as process and document management into a Wiki platform. A field report.

Read more

+